HARDWARE - A SENSE OF DETAIL

Hardware pieces may seem like mere accessories. However, they’re what determine things like fluidity of movement, closure quality, and the structural integrity of the overall creation. A handle, a latch, or a simple metal corner can alter a silhouette, strengthen a line, or even create a visual break.

Hardware acts like a fulcrum between function, aesthetics, and technique. Despite how much a piece of hardware – often standardized and sometimes very intricate – can profoundly transform the product experience, its many personalization options remain surprisingly little-known.

Here at FPM, we see hardware as the ultimate expression of bold choices.

METAL AT ITS SOURCE

When considering hardware, we instantly think of its final purpose: handle, latch, hinge, push button, corner, decorative plate, screw, rivet… In spite of its significance, little thought is given to its raw material.

Every metal has its own personality, density, workability, color, and behavior over time.

- These days, the option featured widely in small-scale hardware and luggage fittings is zamak. This cast alloy – one of the market’s most frequently-used metals – boasts an ability to be molded into very precise shapes and a wide variety of designs.

- Brass, on the other hand, embodies a sense of nobility. It can be polished, varnished, and patinated, but requires highly precise craftsmanship : it’s one of the most sensitive metals, a “living” material that reacts to and is marked by its surroundings.

- Steel and stainless steel, for their part, are sturdy – perfectly suited for precision cutting, bending, and welding. Stainless steel is notably prized for its stability over time and its high-quality appearance.

- Aluminum paves the way for lighter, more modern parts, provided the tooling investment required for casting is assumed.

TRANSFORMING MATERIAL

Before becoming a handle or a clasp, metal goes through a precise industrial process that blends form, constraint, and know-how. There are two main trajectories:

CASTING

This process enables the creation of complex and perfectly repeatable pieces. Die casting is particularly appreciated for its dimensional accuracy: this technique ensures very low tolerances and almost perfect repeatability, making it the ideal solution for large-scale runs. After casting comes the finishing work that is crucial in achieving high luxury standards – deburring, polishing, galvanizing, and varnishing.

MACHINING

This process offers impeccably clean pieces. Machining puts forward a nobler side, ensuring more control, precision and an almost sculptural quality. It creates perfectly defined surfaces, sharp edges, and “mirror-like” finishes that are otherwise impossible to achieve.

THE MAGIC OF FINISHES

Finishing isn’t just about color and shine – it’s about longevity, protection, and aesthetic consistency.

Galvanizing

Using the principles of electrical conductivity, this surface treatment consists of plunging pieces in several dips, alternating chemical solutions with water rinses. In all, this process requires around twenty different steps. Several traditional processes contain heavy metals that are now restricted by the EU REACH regulation, encouraging the market to turn to less harmful alternatives.

Anodizing

Reserved for aluminum, this process deposits a thin layer of protective aluminum oxide (called alumina) by plunging pieces into a series of dips. This layer can also be tinted. Anodizing is now regulated by environmental standards aimed at reducing its impact.

Metallization and PVD

PVD, or Physical Vapor Deposition, consists of a very thin coating applied by deposit, projection, or immersion. Its wealth of color options means this process is currently being explored as a viable alternative.

Varnishing

Applied via spraying, this finishing layer protects pieces from oxidation, harmonizes color, and can enhance the look of a metal left intentionally “rough” and/or be added after a previous surface treatment.

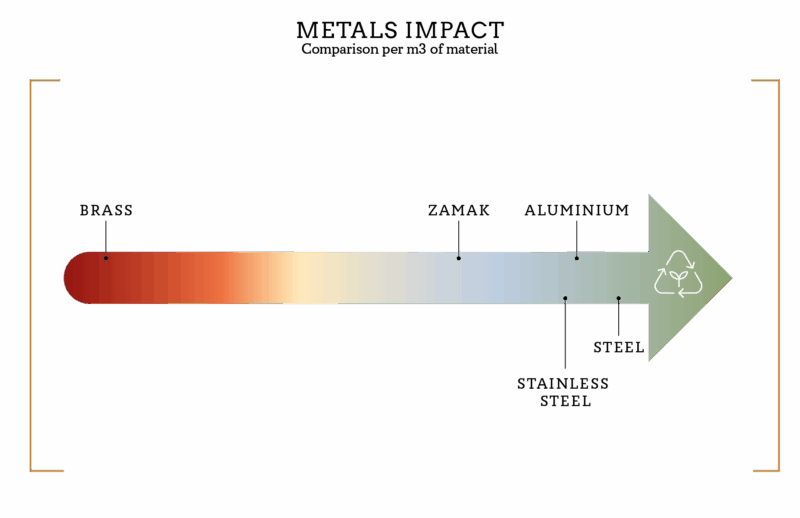

METALS & CSR

Parce que les ferrures sont faites de métal, elles sont au cœur des préoccupations environnementales : matières premières, consommation d’énergie, traitements de surface, recyclage. Dans l’industrie du packaging, la demande pour les métaux recyclés progresse fortement.

However, the impact of these metals can vary substantially. The DIAM group has put together a comparative benchmark for each of the metals used in packaging.

A SMALL PIECE WITH A DECISIVE ROLE

Hardware is not just an accessory. It embodies the final flourish in a design. It’s the culmination of metal, expertise, transformation, and finishing. Sometimes invisible yet always essential, hardware gives the case its personality, movement, and ultimately its soul.

FPM teams